Is fiberglass better than polyester for mosquito nets?

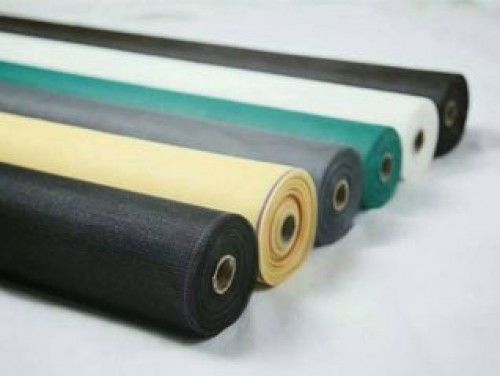

When selecting the suitable material for mosquito nets, weighing the pros and cons of different fabrics is crucial. Two popular choices are fiberglass and polyester, each offering unique benefits and challenges. Mosquito nets are vital in protecting individuals from insect-borne diseases, making their effectiveness, durability, and safety paramount. In this comprehensive analysis, we'll delve into the specifics of fiberglass and polyester mosquito nets, comparing their strength, cost, environmental impact, and overall suitability for various settings. Understanding these factors is essential for making an informed decision that ensures comfort, protection, and long-term usability.

Durability and Strength

Fiberglass:

•Fiberglass nets are known for their durability. They are less prone to tearing and can withstand harsh conditions.

•They are also resistant to rust and corrosion, making them ideal for humid or coastal environments.

•Fiberglass nets maintain shape over time and are less likely to sag.

Polyester:

•Polyester nets are also durable but may be more prone to wear and tear than fiberglass.

•They are less resistant to high temperatures and might degrade faster in harsh weather conditions.

•Polyester nets can lose shape over time, especially if frequently moved or adjusted.

Effectiveness in Mosquito Prevention

Fiberglass:

•Fiberglass nets have a rigid structure, which can effectively prevent mosquitoes from entering.

•The mesh size can be fine-tuned to balance mosquito prevention and airflow.

•They are often coated with PVC or other materials, enhancing their mosquito-repellent properties.

Polyester:

•Polyester nets are highly effective at preventing mosquitoes due to their fine mesh.

•They are more flexible, allowing for a tight fit in various spaces and leaving fewer gaps for mosquitoes to enter.

•However, they might require more frequent inspections for tears or holes where mosquitoes could penetrate.

Cost and Availability

Fiberglass:

•Fiberglass nets are generally more expensive due to their material and manufacturing process.

•They are widely available but might offer fewer options in terms of size and shape.

Polyester:

•Polyester nets are more affordable, making them a cost-effective option for large-scale or budget-conscious projects.

•They are readily available in various sizes and shapes, providing flexibility for different applications.

Environmental Impact and Safety

Fiberglass:

•Fiberglass production has a higher environmental impact, and disposal can be challenging.

•They are non-biodegradable, which can contribute to long-term ecological concerns.

•Fiberglass strands can be harmful if inhaled or come into contact with the skin.

Polyester:

•Polyester is a synthetic material, and its production has an environmental impact.

•However, polyester nets are often lighter and require less material, which can reduce their overall carbon footprint.

•They are safer for direct human contact and do not pose the same health risks as fiberglass.

Maintenance and Cleaning

Fiberglass:

•Fiberglass nets are easier to clean due to their rigid structure and can be wiped down.

•They are less likely to absorb odors or become stained.

Polyester:

•Polyester nets require more careful cleaning to avoid damage.

•They can absorb moisture and odors, necessitating more frequent cleaning.

Aesthetic and Flexibility

Fiberglass:

•Fiberglass nets typically have a more industrial look, which might only be ideal for some settings.

•They offer less flexibility in terms of design and aesthetics.

Polyester:

•Polyester nets are available in various colors and can be more aesthetically pleasing.

•They offer more design flexibility and are suitable for different architectural styles.

Conclusion:

Both fiberglass and polyester mosquito nets have their advantages and disadvantages. Their choice depends on specific needs such as budget, environment, safety concerns, and aesthetic preferences. For long-lasting, low-maintenance applications, fiberglass might be the better choice. However, polyester nets could be more suitable for cost-effectiveness, flexibility, and ease of use. Ultimately, the decision should be based on the specific requirements of the intended use and the environment in which the nets will be used.